Building & Construction

Steel / Heavy Industry

Transportation

Industry / Machinery

Machine Tools

Mining

Oil & Gas

Metrology

Military

Vibration isolation & structural thermal break solutions

Fabreeka brings nearly a century of experience providing vibration isolation and shock control solutions for customers worldwide. Incorporated in 1918, Fabreeka worked with engineers at Goodyear and MIT to develop the original Fabreeka pad, a preformed fabric pad used in impact shock and vibration control. Our range of solutions also includes our Fabcel pad, a cellular, nitrile pad used in industrial applications for reduction of vibration and structure-borne noise, PAL and PLM low frequency pneumatic isolators, expansion and slide bearings and Fabreeka-TIM structural thermal break. Fabreeka’s Stoughton, MA, facility is ISO 9001:2015 certified.

Try Our NEW Calculation Tool to Design Machine Foundations!

Fabreeka News

- New Online Sizing Calculator for Machine Foundation Design

- Fabreeka’s Newest Product FAB-EFP Foundation Isolation

- Introducing new FAB-EPM HP series Foundation Isolation Materials

Products for Thermal Break, Bearing Pads & Impact Shock Control

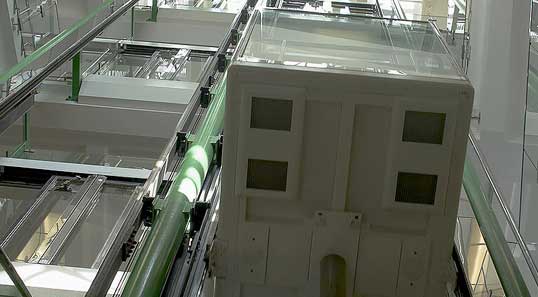

Elevators

Fabreeka pads, washers and bushings have long been used to eliminate objectionable structure-borne noise in buildings from the operation of passenger elevators. The installation of the pad, washer and bushing combination completely isolates the transmission path of structure-borne noise and vibration.

Learn More »

Cranes

Fabreeka Crane Rail pad material is used to reduce vibration, stresses and mechanical wear and tear associated with bridge, gantry and ore crane operation, thereby reducing maintenance costs. Fabreeka Crane Rail pads are designed to relieve girder stress, improve load distribution, eliminate mechanical wear of flange or cover plates, dampen vibration and reduce noise.

Learn More »

Aircraft Testing

Fabreeka has designed a number of “soft support systems” (SSS) using standard and custom pneumatic isolators for ground vibration testing (GVT) of aircraft. To obtain accurate results during GVT, the modal testing of the aircraft requires simulation of a “free-free” condition. To achieve this condition, Fabreeka works with the structural and dynamics testing groups of aircraft manufacturers to design the required SSS for the GVT.

Learn More »